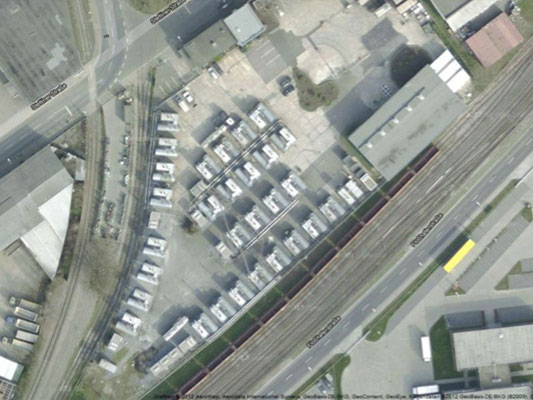

Thermal Power Station Park - Neuss

30 x Volvo Penta Marine Diesel engine

Jochen M. Lippert developed and built in the port of Neuss within 7 months a CHP-park with unique features. With a total of 30 Volvo Penta marine diesel engines housed in containers since 2008, 12 megawatts of electrical power and 12 megawatts of thermal energy have been generated at one

site since 2008!

With a catalyst system developed and patented by Jochen M. Lippert, the exhaust gases of the total of 30 marine diesel engines are filtered. The catalytic converter system falls below all current emission limits. Experts like to refer to the end product as "white energy".

These systems are operated with an engine load of 80 percent at 8,000 hours a year.

Energy is generated exclusively from renewable raw materials and is therefore C02-neutral.

In addition to the technical maturity, the compact design and the simple maintenance options of the entire system are real added value.

HIGHLIGHTS

- Engines: 30 x Volvo Penta marine diesel engine

- Power:

12 MW of electrical energy

12 MW thermal energy - Engine load: 80 % at 8,000 hrs / yr

- Efficiency: > 90 %

- Development and construction time: 7 months (total)

Special features

- System full retrievable power after 18 seconds

- Patented catalyst system

- C02-neutral due to renewable resources as fuel

- Innovative system for shortening service and maintenance times

- Modular design

Energy Project in Indonesia

300 thermal power stations for south-east asia

inhabited more than 6,000 individuals. On some of these islands, 300 thermal power stations have been installed. These are powered by renewable raw materials from domestic cultivation.

The concept reduces the import dependency on global markets and ensures a stable power supply. Even remote areas are supplied with energy in an environmentally friendly self-sufficient manner. This opens up new opportunities for the sustainable production of energy as well as the production of goods and commodities, thereby improving the general living

conditions in previously disadvantaged areas.

In the approval process in accordance with the Federal Emission Control Act, it was found that the exhaust after-treatment technology results in levels that fall below all applicable limits. In some areas, the measurement results are even below the irrelevance limit, thereby conforming to the standards of the country with the most stringent environmental legislation.

In small infrastructure projects, the energy produced by the stations has been provided to the population via area networks. Within

these regional networks, the cooling energy gained from the exhaust heat is used to supply publicly accessible refrigerated warehouses or to cool newly built schools and hospitals.

The exhaust heat (in the form of steam) is used in the production of textiles or for water treatment. The ambitious project also includes the construction of local sewage treatment plants and the use of waste in bio-gas systems and as fertiliser.